Download the entire T.A.I. Fittings catalogue now.

View our price lists online:

- Malleable Cast Iron Fittings Pricelist

- Reduced Fittings List

- Galvanised Barrels Pricelist

- All-Thread Nipples List

- Black ankle boots

The company T.A.I. markets fittings marked ‘EE’ produced by the company Odlewnia Zeliwa according to standard UNI-EN 10242 equivalent to ISO 49. The “EE” fittings allow the connection of pipelines for hot and cold water and drinking water systems (they are certified non-toxic), combustible gas distribution systems, as they meet the standard UNI-CIG 9034 titled: ‘Gas distribution pipelines with maximum operating pressures of 5 bar. Materials and Jointing Systems’.. They also allow the connection of ducts in steam, central heating and fire-fighting systems.

White-core malleable cast iron grade W 40-05 according to ISO 5922 equivalent to EN-GJMW-400-5 according to EN 1562, has a cast iron structure with the following characteristics: a decarbonised surface zone (ferrite), a ferrite-pearlite intermediate zone, a perlite-ferrite-tempered carbon centre zone. Analyses carried out on a 12 mm sample showed the following: tensile strength: min Rm= 400 MPa, elongation: min A3 ≤5%, hardness: max 220 HB; metallographic research showed that the structure complies with ISO 5922 and EN 1562. “EE” fittings are threaded in accordance with standard UNI-EN 10226/1 entitled ‘pipe threads for coupling with thread seal – external conical and internal parallel threads – dimensions, tolerance and designation‘ corresponding to ISO 7/1 and ISO 228/1.

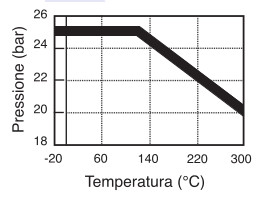

The table opposite shows the maximum permissible working pressure as a function of operating temperature (this applies to all diameters). The fittings can be supplied with a black surface or with a galvanised protective layer at least 70 microns thick.

The table opposite shows the maximum permissible working pressure as a function of operating temperature (this applies to all diameters). The fittings can be supplied with a black surface or with a galvanised protective layer at least 70 microns thick.

Galvanising takes place by hot dipping in a zinc bath according to point 11.2 of ISO 49. The chemical composition of the metal mixture used for immersion is: Zn – min 98.5%, Al – max 0.1%, Sb – max 0.01%, As max 0.02%, Bi – max 0.01%, Cd – max 0.01%, Cu – max 0.1%, Pb – max 1.6%, Sn – max 0.1%. The fittings are tested by applying an internal pneumatic pressure of 0.5MPa, as required by ISO 49 standard 11.4 and UNI 5192. The fittings are marked in accordance with point 14 of ISO 49. The Odlewnia Zeliwa company obtained ISO 9001 certification, certificate no. PL11000185P of 7 July 2011 by Bureau Veritas Quality International.

Our company also sells ‘MD’ marked fittings made of cast iron EN-GJMB-350-10 according to UNI-EN 1562 according to class ‘A’ of UNI-EN 10242.

Threads on fittings are executed according to standard UNI-EN 10226/1 entitled ‘pipe threads for coupling with thread seal – external conical and internal parallel threads – dimensions, tolerance and designation‘ corresponding to ISO 7/1 and ISO 228/1.

Tronchetti Neri

Tronchetti Neri Nippli Tutto Filetto

Nippli Tutto Filetto Barilotti zincati

Barilotti zincati Packaging Raccordi Ridotti

Packaging Raccordi Ridotti